Discover how our chillers work

Updated May 26, 2025

Polypoles, your partner in heating and cooling for professionals

With over 35 years of expertise in heating and cooling systems, Polypoles supports professionals in industry, construction, viticulture and logistics with their cooling needs. We offer a wide range of refrigeration units from 50 kW to 400 kW, available for rental or sale.

Our chillers are designed to ensure optimum performance in the most demanding environments, providing precise temperature control and reliable chilled water production, even in severe conditions.

What is a refrigeration unit?

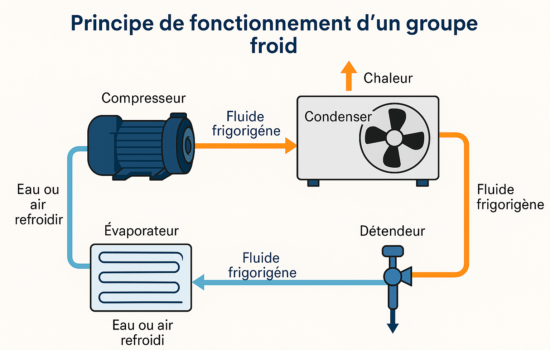

A chiller is an industrial refrigeration system designed to lower the temperature of a fluid or an environment. It is based on a thermodynamic refrigerant cycle that captures heat from point A and rejects it to point B. This process, known as the refrigeration cycle, enables precise thermal conditions to be maintained, which are essential in many professional sectors.

Detailed operation of an industrial chiller

The operation of a refrigeration unit is based on a closed refrigeration cycle, using a refrigerant that changes state (liquid ↔ gas) according to variations in pressure and temperature. This principle enables heat to be captured from one medium and released elsewhere. Here are the key stages in this cycle:

- Refrigerant compression: The compressor draws in the fluid at low pressure and low temperature. By compressing it, it increases its pressure and temperature, transforming cold gas into hot gas at high pressure. ➡️ This stage consumes energy (usually electrical) and is the driving force behind the refrigeration circuit.

- High-pressure gas condensation The fluid is transferred to the condenser, where it transfers its heat to the air or a water circuit. It then changes from a gaseous to a liquid state, while remaining under high pressure. ➡️ The thermal energy is evacuated, enabling cold to be produced in the next stage.

- Fluid expansion The refrigerant flows through the expansion valve, causing a drop in pressure and temperature. The fluid becomes partially gaseous and very cold. ➡️ This stage prepares the fluid to absorb heat from the medium to be cooled.

- Evaporation in the evaporator The fluid enters the evaporator, where it captures heat from the air, water or process fluid. It gradually evaporates, returning to its gaseous state. ➡️ This change of state produces the desired cooling effect.

The refrigerant then returns to the compressor, and the refrigeration circuit starts all over again. This continuous operation guarantees a stable temperature tailored to the needs of each industrial plant.

Chiller types and professional applications

At Polypoles, we offer chillers for every sector:

- Mono chiller : HLi range industrial chillers provide chilled water for your wine-making, industrial or commercial processes. Working temperatures from -10°C to 42°C and water settings from -5°C to 35°C. Ideal for industry and events, with our FP and HLBG fan coil ranges.

- Three-phase chiller The HLi three-phase chiller range produces chilled water from -5°C to 15°C at ambient temperatures from -10°C to 43°C. Ideal for industry and events, combined with FP30, FP50 or HLBG fan coils, or directly connected to your process.

Fields of application

Our solutions are used in demanding environments:

- Food industry

- Events

- Viticulture

- Pharmaceutical industry

- Logistics and cold storage

- Retail

Energy optimization and maintenance

Our chiller rentals are designed for optimum energy efficiency:

- Modern technologies reduce energy consumption.

- Use of refrigerants with low environmental impact.

- Advanced control systems to adjust power to the actual thermal load.

We also provide maintenance, guaranteeing the reliability of the refrigeration circuit and the longevity of the equipment.

Why choose Polypoles for your refrigeration project?

✅ Recognized expertise for 35 years

✅ Immediate availability of our equipment

✅ Energy efficiency and respect for the environment

✅ Rental or sale

✅ Complete support from analysis to maintenance

What’s the difference between chilled water and brine?

In refrigeration systems, two types of fluid are frequently used for cold distribution: chilled water and glycol water. Their use depends on the type of system and operating conditions.

-

Chilled water is pure water, used when operating temperatures remain above 0°C. It offers excellent heat exchange capacity, but freezes below 0°C. This makes it ideal for air-conditioning systems, moderate industrial processes and air handling units.

-

Glycol water is a mixture of water and glycol (ethylene or propylene). The glycol lowers the liquid’s freezing point, enabling it to be used in outdoor or low-temperature environments. This fluid is recommended for installations exposed to freezing (outdoor systems, open hydraulic circuits, etc.).

Remember: Chilled water is thermally more efficient, but cannot withstand frost. Glycol water is essential to guarantee the safety of a circuit subject to low temperatures.

Get your customized quote

You are looking for a refrigeration solution and adapted to your industrial constraints? Contact Polypoles for a personalized quotation. Our design office and technical sales staff will respond precisely to your needs.

Discover our complete range of chillers chillers here

About the author

Pierre Perrinet

Arts et Métiers engineer, manager and president of Polypoles for over 25 years, expert in air conditioning, heating, ventilation and air treatment.